GP Sheet

Price 90 INR/ Kilograms

GP Sheet Specification

- Coating Type

- Zinc coating (Galvanization)

- Weight

- Varies by thickness and size

- Application

- Construction, Automobile, Electrical, Industrial

- Dimension (L*W*H)

- Custom sizes available, standard sizes up to 2500 mm x 1250 mm

- Mount Type

- Direct mounting, welding, riveting

- Usage

- Paneling, Roofing, Ducting, Fabrication

- Shape

- Rectangular

- Hole Size

- Custom/perforated options available

- Components

- Sheets, Plates

- Surface Finishing

- Smooth, Matte or Glossy

- Material

- Galvanized Iron (GI)

- Tolerance

- 0.5 mm

- Thickness

- 0.3 mm to 3.0 mm

- Capacity

- Suitable for heavy loads depending on thickness

- Surface Treatment

- Galvanized, Zinc Coated

- Making Process

- Cold Rolled

GP Sheet Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash Advance (CA)

- Main Domestic Market

- North India

About GP Sheet

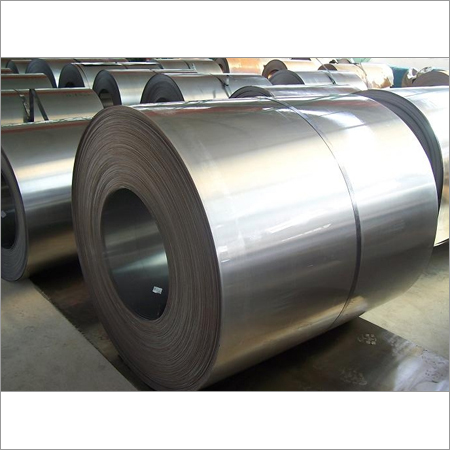

GP Sheet

Our client can get GC Sheet from our firm with assurance of quality. Offered sheet is available in different designs, sizes, thicknesses, shapes and dimensions. We sourced GC Sheet from the well-established vendors of the market. Offered sheet is manufactured at our vendors end using ultra-grade grade steel, aluminum and other basic raw materials. Owing to its excellent tensile strength, sturdiness, superior finish, longer service life and quality as per the international standards, our GC Sheet is highly acclaimed by the patrons.

Our firm is counted amongst the well-recognized traders and suppliers of GP Sheet. It is available in different specifications such as plain, in coils, corrugated and profiled. With its customized design, thickness, size and length, it proves to be highly suitable for making different kinds of sheds, roofing and many others. Owing to its sturdiness, toughness, corrosion resistance, brightness andcrack-free nature, offered GP Sheet is highly acclaimed by the clients. We sourced this sheet from the trusted vendors and tested at our end on different parameters.We are mainly supply these products in Delhi & NCR.

Application:

-

Ducting /Cooler body building/Doors/Windows /Cable Tray/& other Industrial items

Features:

-

Maximum life

-

Available in dimensions and thickness to suit the specific needs

-

Assured performance

Specifications:

-

Surface treatment: galvanized

-

Several lengths are available

-

Width: custom made

-

Tolerance: -0.02+0.02mm

-

Thickness: 0.2-3.0mm

Versatile Application Across Industries

GP Sheets are widely recognized for their adaptability, making them suitable for construction, automotive bodies, electrical panels, and industrial ducting. Their customizable dimensions and range of thicknesses make them an essential material for both light and heavy-duty applications. Whether for paneling, roofing, or fabrication, these sheets deliver reliability and performance.

Superior Protection with Galvanization

Our GP Sheets undergo a zinc coating (galvanization) process, enhancing resistance to corrosion and rust. This ensures a longer lifespan, especially in environments exposed to moisture or fluctuating weather. Clients can also choose between smooth, matte, or glossy surface finishes, tailored to specific aesthetic and functional requirements.

FAQs of GP Sheet:

Q: How do I select the correct thickness for my GP Sheet application?

A: To determine the appropriate thickness, consider the load requirements and application. For heavy-duty constructions, thicker sheets (closer to 3.0 mm) offer enhanced strength, while lighter panels or ducting may require only 0.31.0 mm.Q: What customization options are available for GP Sheets?

A: We provide custom dimensions, perforation patterns, as well as surface finishes (smooth, matte, or glossy) to suit your projects specifications. The hole size can be tailored for ventilation, filtration, or design purposes.Q: When should I opt for galvanized sheets over regular steel?

A: Galvanized sheets are ideal when corrosion resistance is necessarysuch as in outdoor, moist, or chemical-exposed settings. The zinc coating protects the sheet from rust and drastically enhances longevity compared to regular steel.Q: Where can GP Sheets be installed or mounted?

A: These sheets can be directly mounted using fasteners, welding, or riveting. They can be integrated into structural frameworks, roofs, ducting, and various industrial assemblies, offering flexible installation across different settings.Q: What is the manufacturing process of your GP Sheets?

A: Our GP Sheets are produced via a cold rolling method, giving them a uniform thickness and smooth surface. The sheets are then zinc coated by galvanization to improve durability and finish.Q: How does using galvanized GI Sheets benefit my project?

A: The key benefits include extended service life due to corrosion resistance, low maintenance, and versatility across numerous applications. The smooth or matte finish also improves aesthetic value for exposed installations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry